-

-

Company

-

Product

-

Products Overview

-

NdFeB Magnets

-

SmCo Magnets

-

AlNiCo Magnets

-

Ferrite Magnets

-

Bonded Magnets

-

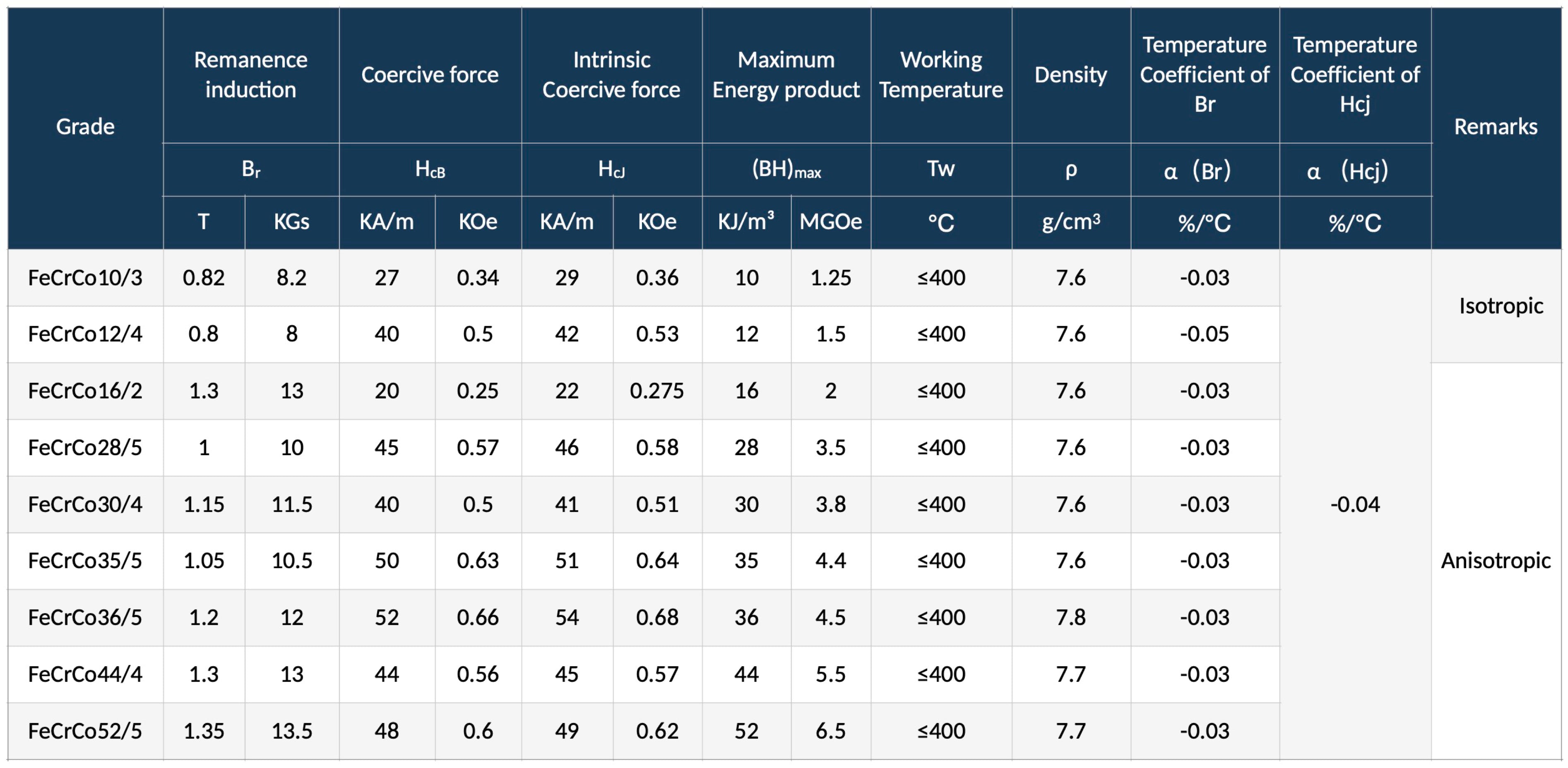

FeCrCo Magnets

-

Rubber Magnets

-

Other Magnetic Materials

-

Nanocrystalline Core

-

Common Mode Inductors

-

Amorphous Inductors

-

Amorphous Reactors

-

AlNiCo Holding Magnets

-

NdFeB Holding Magnets

-

Magnetic Lifters

-

Magnetic Tubes & Grates

-

Halbach Arrays

-

Rosolver

-

Overmolding Magnets

-

Customized Magnetic Assemblies

-

PIM Parts

-

-

Capabilities

-

Resources

-

Contact

-

Subscription

-

-

Company

-

Product

-

NdFeB Magnets

-

SmCo Magnets

-

AlNiCo Magnets

-

Ferrite Magnets

-

Bonded Magnets

-

FeCrCo Magnets

-

Rubber Magnets

-

Other Magnetic Materials

-

Nanocrystalline Core

-

Common Mode Inductors

-

Amorphous Inductors

-

Amorphous Reactors

-

AlNiCo Holding Magnets

-

NdFeB Holding Magnets

-

Magntic Lifters

-

Magnetic Tubes & Grates

-

Halbach Arrays

-

Resolver

-

Overmolding Magnets

-

Customized Magnet Assemblies

-

Powder Injection Parts

-

-

Capabilities

-

Resources

-

Contact

-

Subscription