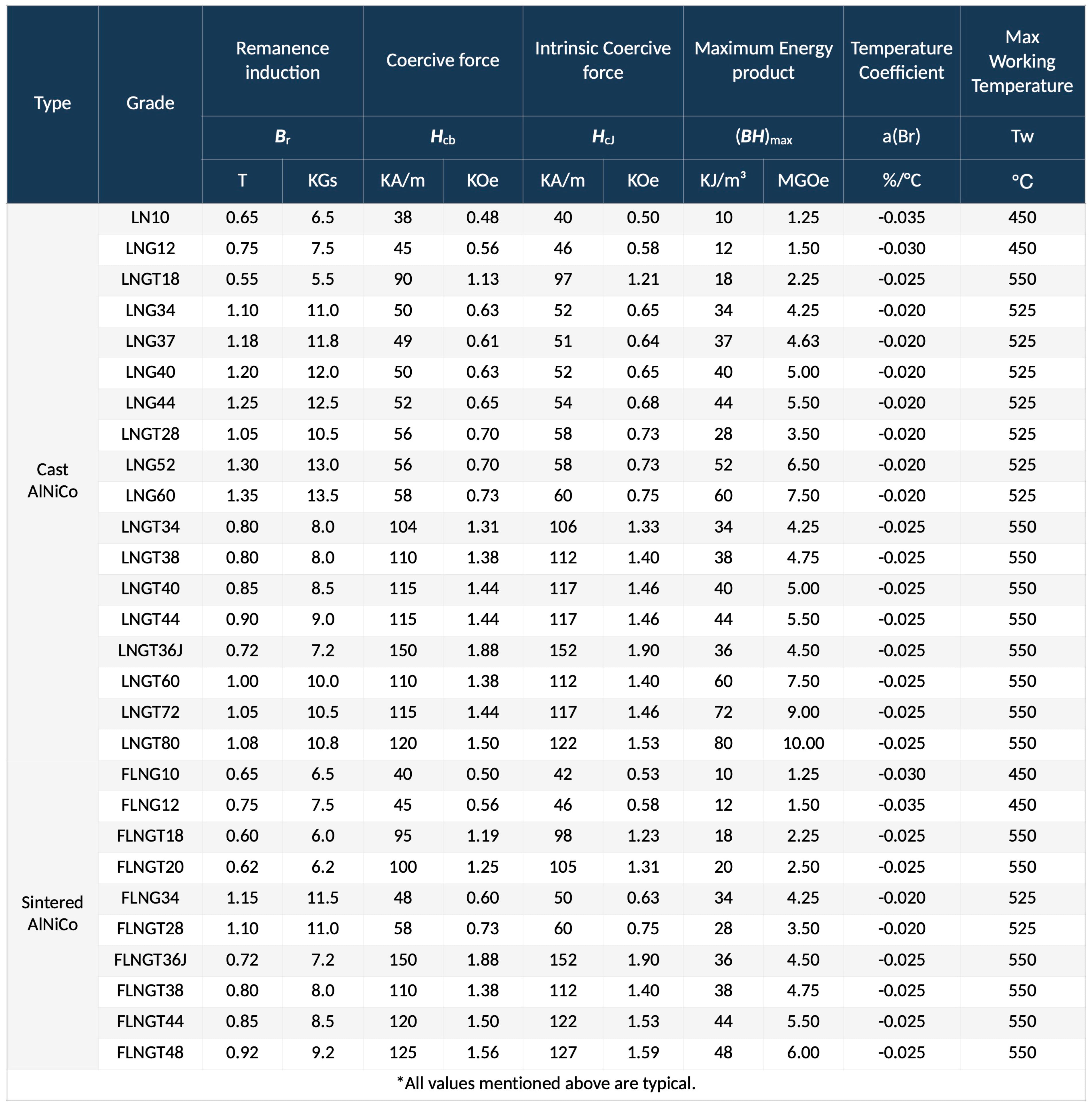

First used in the 1930’s, Alnico is the oldest family of permanent magnets. With energy products ranging from 1.3 to 10.1 MGOe, Alnico can be produced in both cast and sintered forms. The most common grades are cast Alnico 5 and 8 with Alnico 5-7 and 9 being premium grades. Sintered Alnico materials are used in applications where the geometries are smaller and more complex.

Alnico magnets are easy to magnetize and have high resistance to corrosion. They are used where high temperatures exist and/or where very stable properties are required.

Cast AlNiCo

Cast Alnico is the permanent magnet material successfully developed in the 1930s.

Its composition is typically 8–12% Al, 15–26% Ni, 5–24% Co, up to 6% Cu, up to 1% Ti, and the balance is Fe.

The advantages of Cast Alnico magnet are high remanence Br (up to 1.35 T) and good temperature coefficient and the high maximum operating temperature (up to 538 °C) and corrosion resistance.

Cast Alnico magnets are widely used in sensors, speakers, and meters and etc.

Sintered AlNiCo

Compared to Cast AlNiCo, Sintered AlNiCo is of smaller sizes, complex shape and better machinability, but its magnetic properties are slightly lower.

It is applied for micro-motors, instrumentation, communications, magneto-electricity switches and various sensors, etc.